Error message

Warning: file_get_contents(http://ipinfo.io/3.133.138.31/country): failed to open stream: HTTP request failed! HTTP/1.0 429 Too Many Requests in include_once() (line 656 of /home/closuretesting/public_html/sites/default/settings.php).Unlimited capability for torque testing all closure system designs

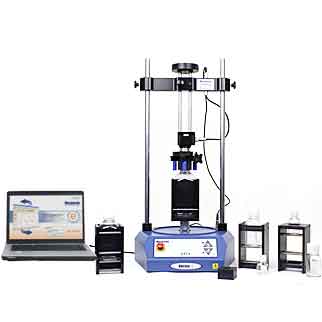

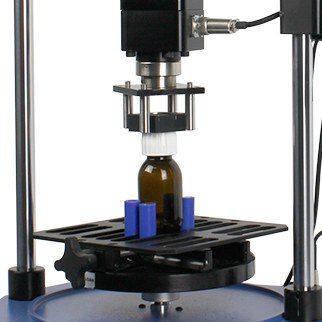

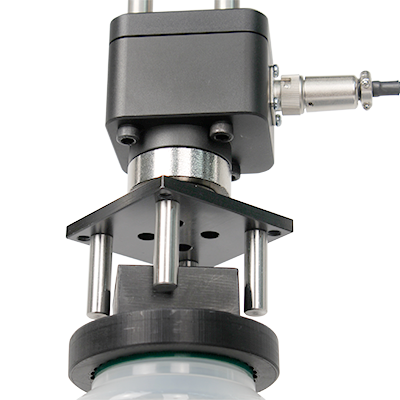

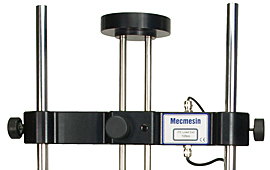

The Vortex-i motorised torque testing system provides constant rotational speed to enable accurate, repeatable, closure torque measurement. Top-loading allows push and turn CRCs to be tested and the ability to write advanced test programs gives designers the power to optimise functionality.

Run sophisticated routines for closure system product development and design optimisation.

Run sophisticated routines for closure system product development and design optimisation.

For TE closures, Vortex has the sensitivity to detect:

For TE closures, Vortex has the sensitivity to detect:

For CRCs, masses are added to the top-load carrier to apply a constant down force while rotating the closure and measuring the release torque.

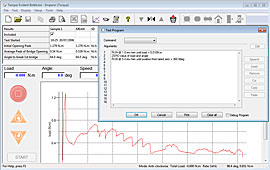

When further evaluation of results is required, a range of calculations are available to help pinpoint areas of interest, for example to accurately differentiate between the breakaway torque peak and the tamper evident band breakage event. Standard and customisable report templates enable easy documentation creation, which can be stored and exported to Microsoft Excel® and SPC packages.

When further evaluation of results is required, a range of calculations are available to help pinpoint areas of interest, for example to accurately differentiate between the breakaway torque peak and the tamper evident band breakage event. Standard and customisable report templates enable easy documentation creation, which can be stored and exported to Microsoft Excel® and SPC packages. Console Mode allows tests to be created very simply by selecting options from radio-buttons and drop-down boxes. A number of pre-configured calculations are available and can be included by simply clicking with the mouse. Console mode is ideal for use on the factory floor by operators who need only minimal training to load and run programs directly from one of the five “Favourite” buttons.

Console Mode allows tests to be created very simply by selecting options from radio-buttons and drop-down boxes. A number of pre-configured calculations are available and can be included by simply clicking with the mouse. Console mode is ideal for use on the factory floor by operators who need only minimal training to load and run programs directly from one of the five “Favourite” buttons.* measured with upper and lower mounting tables fitted

Contact Mecmesin

Got a question about this product?

Our technical sales engineers can help find the right solution for your testing requirements and provide online equipment demos with your samples.

Accessories for this System

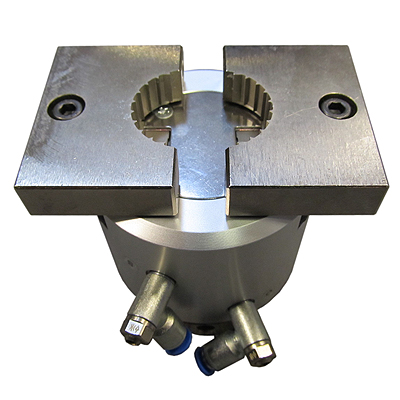

| Large saddle plate | Stelvin aluminium closure split mandrel, pneumatic | Split-mandrel cork grip | Upper keyless chuck, square drive |

| Lower keyless chuck, large, round shaft | Lower keyless chuck small | Pneumatic lift mechanism, Vortex | Dedicated moulded mandrels |

| Dust cover, MultiTest and Vortex | Torque reference bottle | Reference bottle drive adapter | Orbis and Tornado Mk II/Vortex torque cell accuracy check rig |

| Stelvin aluminium closure split mandrel | Lower fixing plate | Upper fixing plate | Custom closure mandrels |

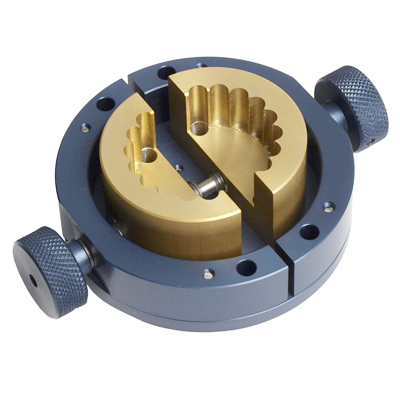

| Custom closure split mandrels | CRC mandrel | V-jaw vice clamp, three jaws with quick lock and release lever for Orbis, Tornado, Vortex | V-jaw vice clamp, three jaws with screw adjustment for Orbis, Tornado, Vortex |

| Mandrel Peg Drive, 54 mm |