Error message

Warning: file_get_contents(http://ipinfo.io/3.145.176.131/country): failed to open stream: HTTP request failed! HTTP/1.0 429 Too Many Requests in include_once() (line 656 of /home/closuretesting/public_html/sites/default/settings.php).Unlimited capability to force test of all types of closure systems

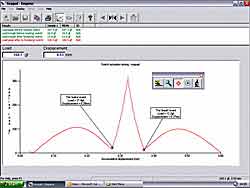

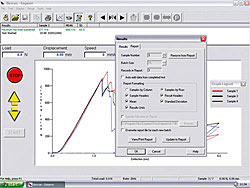

The Mecmesin MultiTest 2.5-i test frame sets the standard in computer-controlled testing, operating through the power of EmperorTM; easy-to-use yet powerful force testing and analysis software. The ability to program sophisticated procedures, based on international legislation or in-house test standards, enables the optimisation of quality, integrity, performance and functionality in corks, stoppers and dispensing cap closures.

Create your own library and run sophisticated routines for closure system product development and design optimisation.

Create your own library and run sophisticated routines for closure system product development and design optimisation.

For pull/push closures and dispensing caps, MultiTest-i has the capability to measure:

For pull/push closures and dispensing caps, MultiTest-i has the capability to measure:

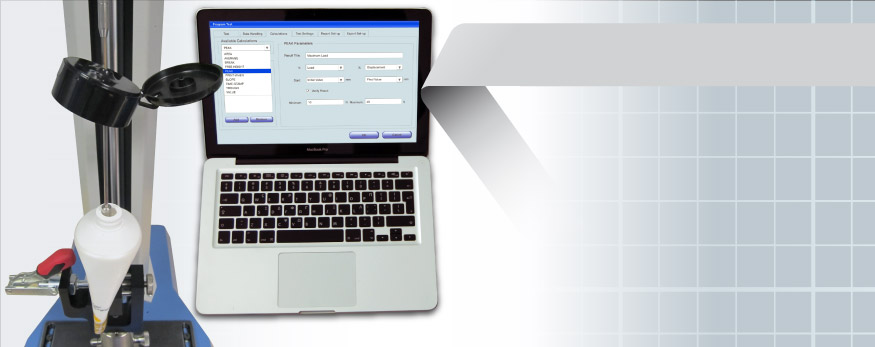

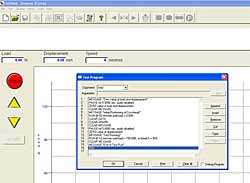

Console Mode allows tests to be created very simply by selecting options from radio-buttons and drop-down boxes. A number of pre-configured calculations are available and can be included by simply clicking with the mouse. Console mode is ideal for use on the factory floor by operators who need only minimal training to load and run programs directly from one of the five “Favourite” buttons.

Console Mode allows tests to be created very simply by selecting options from radio-buttons and drop-down boxes. A number of pre-configured calculations are available and can be included by simply clicking with the mouse. Console mode is ideal for use on the factory floor by operators who need only minimal training to load and run programs directly from one of the five “Favourite” buttons.

* measured without loadcell or grips (see technical datasheet for loadcell measurements)

Contact Mecmesin

Got a question about this product?

Our technical sales engineers can help find the right solution for your testing requirements and provide online equipment demos with your samples.

Accessories for this System

| Large container holder (4-peg adjustable) | Small container holder (4-peg adjustable) | Flip cap accessory | Swivel test hook |

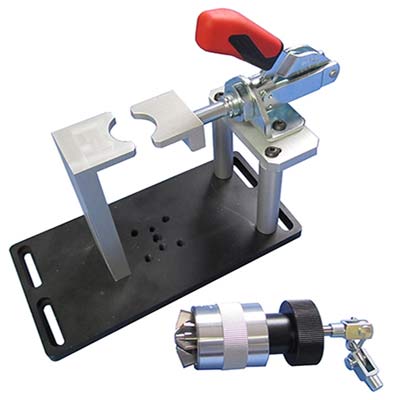

| Small pinch grip | Cork extraction test jig - 1000N | Dust cover, MultiTest and Vortex | Sports cap closure pull-off fixture |

| Metal inner seal peel testing fixture | Adjustable V-jaws | Container valve pull-out fixtures | Pump dispenser container fixture |

| Flip cap attachment strength fixtures | Pull-off fixtures for metal closure and container | 432-677 V-jaw vice clamp, three jaws with quick lock and release lever | 432-678 V-jaw vice clamp, four jaws with screw-action adjustment |