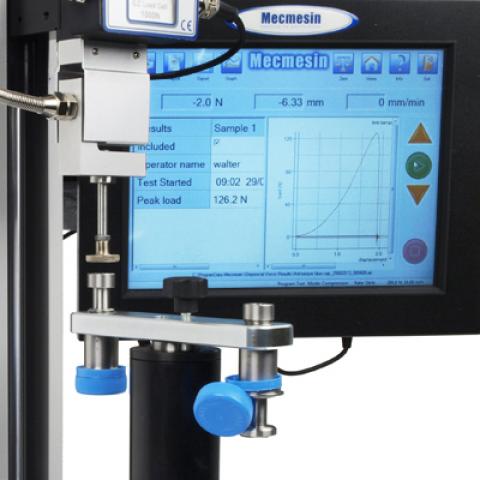

Online test equipment and training demos

As more people are working from home to reduce non-essential travel, our technical sales engineers can provide online equipment demos or training sessions via web-based video calls.

If possible, send in your own samples and our sales team will be able to present your own products being tested.

Get in touch to discuss your requirements and to arrange an online demo or training session.