Error message

Warning: file_get_contents(http://ipinfo.io/3.145.171.111/country): failed to open stream: HTTP request failed! HTTP/1.0 429 Too Many Requests in include_once() (line 656 of /home/closuretesting/public_html/sites/default/settings.php).Specification

A repeatable test system to check the opening force of flip cap lids, accommodating 3 different diameter caps with minimal fixture changeover. Prevention of accidental loadcell damage was also a pre-requisite as this had been a problem previously at Betts Ltd. (now part of Albea).

Solution

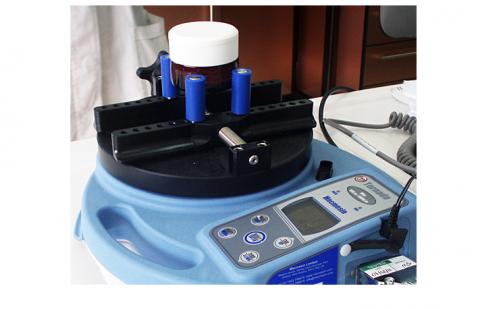

Mecmesin offered a complete solution to the problem, manufacturing a set of mandrels for each cap diameter, which orientated the flip section of the cap in the correct position under the loadcell probe. Time was spent over comparative testing with overseas factories in the Betts group to prove the accuracy and repeatability of the test system. A micro-switch assembly was fitted to the test system, preventing operation of the system unless the product was located fully home in the correct position. This eliminated the high level of damaged loadcells. The solution was provided at a relatively low cost in comparison to the system currently used in the Betts test lab. Mecmesin were also able to offer a unique fixturing and design service.

System supplied

The original solution included:

Product

System supplied to Betts, UK.