Specification

Elopak required equipment for the manual testing of tamper-proof seals on bottle caps, but without the bottle being present. The unit had to accommodate a range of different size caps.

Solution

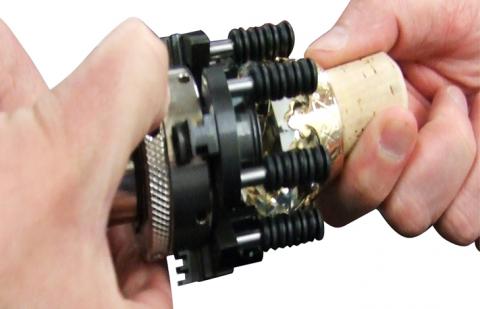

Dedicated 'release fixtures' and 'mandrels' were designed to suit the different caps. The 'release fixture' is made from a mould of the cap ensuring a tight fit and distributing the load uniformly around the cap so there is no deformation due to squeezing by hand which could affect results. An internal mandrel which fits the splines on the inside of the tamper-proof ring was fixed to a static torque transducer linked to an AFTI display and the cap placed on top. The external mandrel was placed on top of the cap and twisted by hand. The peak torque reading was then recorded on the AFTI display. The display and transducer were supplied fixed to a tray with holders for the different mandrels and release fixtures to make it easy for the user to store the equipment.

System

Supplied to: Elopak, Norway